Your Manufacturing solution!

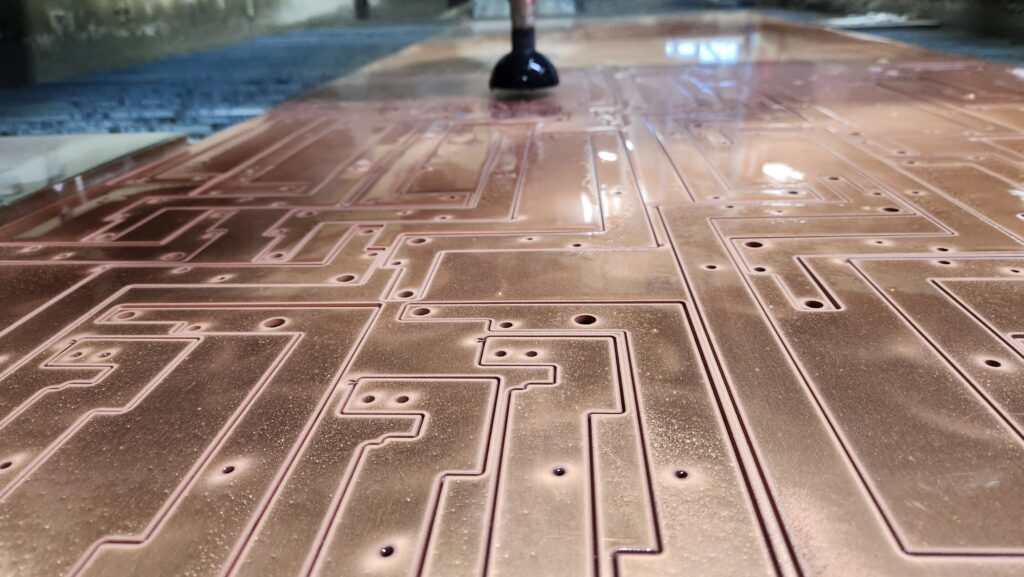

As one of the largest Waterjet shops in Socal we’re here to support your Company. From single prototypes to high volume contract manufacturing we are your partner in production.

- Rush Orders

- Quality Systems

- Highest Accuracy